Many power woodworking tools such as saws and sanders have a provision for connecting a vacuum cleaner hose to suck up the dust and debris produced by their operation. The problem is of course that the vacuum cleaner must be switched on when the tool is switched on and as the operator’s attention must be directed towards the work in hand especially when a blade with large teeth is spinning only inches from his fingers, there is often little incentive to look away to locate the vacuum cleaner switch. This unit was designed to fulfill this function by automatically switching on the vacuum cleaner when the power tool is switched on.

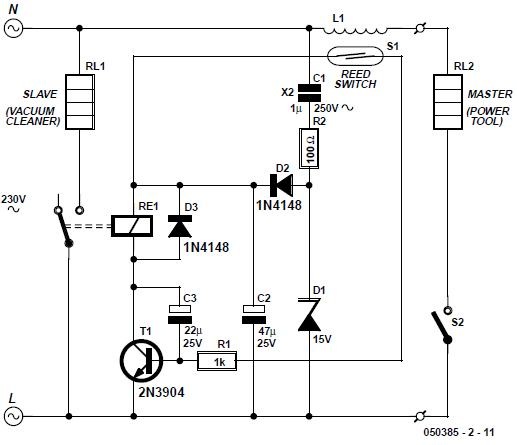

In this circuit, current flow is sensed using a reed relay which is not only cheap but provides a positive indication that current is flowing and dissipates very little power. Reed switches are often used in burglar alarms where they sense the magnetic field from a small magnet but

it is also possible to produce a magnetic field by winding a coil around the reed switch and passing a current through this. The circuit diagram shows a simple mains slave switch based on this idea. The coil may be wound directly onto the reed switch using insulated single core hook-up wire or enamelled copper wire of sufficient gauge to carry the current drawn by the power tool (or master appliance). In practice this should be as thick as possible to cater for any power appliance while still enabling a sufficient number of turns to be accommodated to produce the required magnetic field which will depend on the reed switch and is therefore best determined by experiment. As a guide, a one-inch reed switch with 40 turns reliably switched on with the current flowing through a 150-watt lamp (approx. 625 mA) but larger reeds may require more turns. If the master appliance draws less current (which is unlikely with power tools) more turns will be required. The reed switch is used to switch on transistor

T1 which in turn switches the relay RE1 and powers the slave appliance.

Author: Bart Trepak

(Elektor Electronics Magazine – 2006)

| * Download this article. |

Labels

- * Elektor 2005 (9)

- * Elektor 2006 (72)

- Adapters (1)

- ADC / DAC (1)

- AM / FM (2)

- Amplifiers (3)

- Antennae (2)

- Articles List (1)

- Audio (1)

- Automatic (2)

- Batteries (3)

- Bluetooth (1)

- Breakers / Contacts (1)

- Buzzers / Sirens (1)

- Clocks / Timers (2)

- Computer (2)

- Converters (2)

- Coolers / Fans (1)

- Counters (1)

- Datasheets (7)

- E-blocks (1)

- Energy (2)

- Flash / Light (8)

- Frequency (1)

- Fuse (1)

- Generators (2)

- High-voltage (1)

- Indicators (2)

- Infrared (IR) (4)

- LCDs (1)

- LEDs (7)

- Magazines (1)

- Meters (5)

- Microcontroller (9)

- Mobile Phone (1)

- Motors (1)

- OPAMP (3)

- PCB (1)

- Photosensors (1)

- Power Supply (2)

- Preamplifiers (1)

- Programming (3)

- Radio (1)

- Rectifiers (1)

- Regulators (1)

- Relays / Switches (10)

- Remote Control (7)

- RS232 (3)

- Security (4)

- Sensors (2)

- Servo (2)

- Simulators (1)

- Small Circuits (46)

- Telephones (2)

- TENS (1)

- Testers (3)

- Timebase (1)

- Tools (1)

- Transmitters (1)

- Trigger (1)

- USB (2)

0 comments: